Are Leather Gloves Good for Welding

Yes, leather gloves are good for welding.

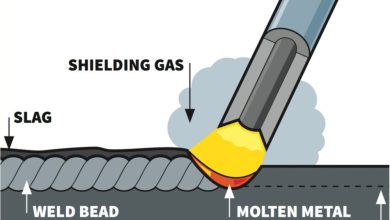

Leather is commonly used in welding because it offers protection against molten metal, electricity, and intense light.

There are different types of leather used in welding, such as cowhide, elkskin, pigskin, and goatskin, each offering specific benefits.

Factors to consider when selecting welding gloves include heat and temperature exposure, insulation provided, glove length, and protection against sparks and spatter.

It is recommended to choose gloves specifically designed for welding, taking into account the type of welding being done.

Higher-quality leather provides better protection, and the choice should be based on the specific welding technique and the required level of protection.

Did You Know?

1. Leather gloves for welding were originally designed for the aerospace industry to protect workers from the intense heat generated during the manufacturing of parts for space shuttles and rockets.

2. The thick leather used in welding gloves is not only heat-resistant but also provides excellent protection against sparks, hot metal, and abrasions. However, it is important to note that leather gloves should not be worn near open flames or in extremely high-temperature settings.

3. While leather gloves can withstand the heat produced during welding, they are not suitable for protecting against electrical shock. Electricians and welders working with electrical components and circuits should use specialized gloves designed for electrical safety.

4. Leather gloves used for welding are typically made from cowhide or goatskin due to their durability and resistance to heat. Goat leathers are known to be more dexterous and offer better grip, making them a preferred choice for some welders.

5. Leather gloves should fit snugly to provide maximum protection and maneuverability. It is recommended to choose gloves with a long cuff, as they provide additional coverage to protect the forearms from sparks and molten metal.

Types Of Leather Used In Welding

Leather is a common material used in welding to protect workers from molten metal, electricity, and intense light. There are four common types of leathers used in welding: cowhide, elkskin, pigskin, and goatskin.

Cowhide is the most common leather used in welding due to its abundance and durability. It provides excellent protection against heat, sparks, and splatter. Cowhide gloves are typically lined with wool for insulation and are resistant to flames and static electricity.

Elkskin leather is another popular choice for welding gloves. It is highly durable, heat-resistant, flame-resistant, and abrasion-resistant. Elkskin gloves also offer great dexterity, allowing welders to easily handle tools and materials.

Pigskin leather, while not as flexible as other leathers, is dense and tough. It allows the wearer’s skin to breathe, making it more comfortable for longer periods of use. Pigskin gloves are known for their durability and are often used in heavy-duty welding applications.

Goatskin leather is thin and flexible, offering excellent protection against cuts and abrasion. It is a preferred choice for TIG welding, as it provides good fingertip sensitivity and dexterity.

Benefits Of Different Types Of Leather

The different types of leather used in welding offer various benefits based on their characteristics. Cowhide is the most widely used leather due to its durability and ample availability. It provides excellent protection against heat, sparks, and splatters.

Elkskin leather is highly durable and resistant to heat, flames, and abrasion. Welders who prioritize durability and require protection against intense heat often choose elkskin gloves.

Pigskin leather, although less flexible than other leathers, is known for its durability and breathability. This type of leather allows the wearer’s skin to breathe, reducing discomfort during long welding sessions.

Goatskin leather is thin and flexible, providing superior dexterity and protection against cuts and abrasion. It is particularly favored for TIG welding, where fingertip sensitivity is crucial.

Other types of leather, such as kidskin, deerskin, and sheepskin, offer unique properties as well. Kidskin is soft and lightweight, providing good fingertip sensitivity and durability. Deerskin is tough, lightweight, and can regain its shape and softness even after getting wet. Sheepskin is thin, elastic, and contains natural lanolin, which helps in healing the skin. These types of leather may be suitable for specific welding situations or personal preferences.

Factors To Consider When Selecting Gloves

When selecting welding gloves, several factors should be taken into consideration to ensure the glove’s suitability for the job. These factors include:

-

Heat and temperature exposure: Assess the level of heat and temperature exposure before choosing welding gloves. Different welding techniques generate varying levels of heat and may require gloves with higher heat resistance.

-

Handling time: Some gloves may become uncomfortable when used for extended periods. Consider the handling time and ensure the gloves provide adequate comfort.

-

Insulation provided: It is essential to consider the insulation provided by the gloves, especially when working in cold environments or with materials that retain low temperatures.

-

Glove length: Longer gloves offer better arm and wrist protection against sparks and splatter. They are particularly important for stick welding, where high heat and splattering may occur.

-

Flame-resistant material: The material used for threads and seams should be flame-resistant to prevent them from igniting in case of sparks or splatter exposure.

By considering these factors, you can select welding gloves that are appropriate for the job and ensure the safety and comfort of the welder.

Importance Of Choosing The Right Welding Gloves

Choosing the right welding gloves is crucial for the safety and well-being of welders. Welding poses numerous hazards, including extreme heat, sparks, splatter, and electrical exposure. Properly selected gloves provide protection against these dangers and prevent severe burns, cuts, and injuries.

Good heat protection is of utmost importance when choosing welding gloves. They must insulate against burns from hot materials and surfaces encountered during welding.

Dexterity is also essential. Welders need to handle tools, electrodes, and materials with precision, requiring gloves that offer a good grip and allow for finger movement.

Durability should be another major consideration. Welders often work in harsh environments, subjecting their gloves to constant wear and tear. Choosing gloves made from high-quality leather increases their likelihood of withstanding the rigors of welding work. This ensures they last longer and provide reliable protection.

Protection against cuts is vital, given the sharp edges of materials being welded. The right gloves must shield against abrasion and cuts, without compromising dexterity and flexibility.

Recommendations For Gloves Based On Welding Technique

The choice of welding gloves should be based on the specific welding technique being employed. Different techniques generate various levels of heat and expose the welder to different hazards. Here are some recommendations for gloves based on welding techniques:

-

For TIG welding, gloves made of goatskin with keystone thumbs are recommended. Goatskin gloves offer excellent dexterity, allowing for precise control over the torch and electrode.

-

For MIG welding, gloves made of lined goat or cow grain, or heavier weight cow split gloves are recommended. These gloves provide adequate protection against heat, sparks, and splatter encountered in MIG welding operations.

-

For stick welding, heavy-duty gloves that cover more than just the hands are recommended. These gloves should have a good lining and offer high heat and splattering protection. Stick welding often produces the most extreme heat and splatter, so proper hand and arm coverage is essential.

It is important to remember that the choice of welding gloves should be based on the specific welding technique and the required level of protection. Price and performance should also be considered to strike a balance between affordability and effectiveness.

Check this out:

Frequently Asked Questions

What kind of gloves do you use for welding?

When it comes to choosing gloves for welding, it is important to prioritize a good lining and high-quality leather. Opting for gloves made from materials such as elk skin, cowhide, deerskin, pigskin, or goatskin will ensure adequate protection. The various types of leather offer different levels of durability and resistance, allowing welders to find the perfect balance between comfort and safety for their specific needs. Remember, investing in gloves with superior quality leather will ultimately offer superior protection.

What leather is best for welding gloves?

When it comes to welding gloves, one of the best leather options is cowhide. Cowhide leather provides the ideal combination of performance and value, making it highly suitable for welding tasks as well as for driving and other work-related activities. Its ability to withstand sparks and spatter, along with its supple nature for comfort, makes cowhide a top choice for welding gloves. Additionally, its resistance to dirt and water further enhances its durability and longevity in demanding environments.

Can you weld in leather?

Yes, it is possible to weld in leather, although it is not a common practice. The most commonly used types of leather for welding are cowhide, elkskin, pigskin, and goatskin. Each of these types has specific cuts and grades, ensuring the leather is suitable for heat- and fire-related work. Additionally, there are other types of leather available, including deerskin, kidskin, and sheepskin, each with its own unique properties. When choosing leather for welding, it is important to consider the grain type, with top grain and split being the two most common options.

Welding in leather requires careful selection and preparation of the material to ensure its durability and protection. The leather must have adequate thickness and be resistant to heat, sparks, and flames. Proper safety precautions should be followed, including wearing appropriate protective gear, such as welding sleeves and gloves. Although not commonly utilized, welding in leather can offer a unique and specialized solution for certain heat- and fire-related applications.

What are the best welding gloves?

One of the top welding gloves available on the market is the Tillman 750 Welding Gloves. These gloves are made from premium top-grain elk skin, offering exceptional durability and heat resistance. With its reinforced patches and Kevlar stitching, the Tillman 750 gloves provide excellent protection and a longer lifespan, making them ideal for MIG and stick welding. Additionally, the gloves are designed with a seamless index finger, enhancing dexterity and allowing for precise control during welding tasks.